ProductsDetails

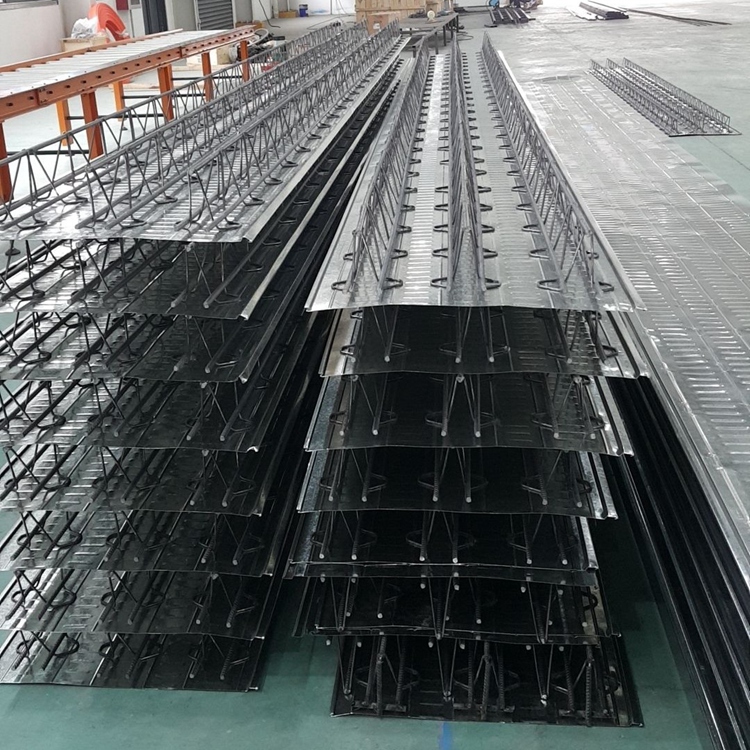

Truss floor support plate

In order to solve the many shortcomings of the first and second generation steel decks, such as the smaller net height of the building, engineers developed the third generation steel truss steel deck. The third generation floor deck was reduced in size by changing the original height. For the convex high-pressure floor decking type, the steel bars in the floor slab are processed into steel trusses using semi-automatic sheet metal welding equipment in the factory to replace the convex height and bearing capacity of the floor decking. After welding, the steel truss and floor decking are integrated into a combined formwork using high-frequency resist welding in the factory using rust removal, rust prevention and environmental protection technology such as silanization, pure manganese phosphating, water washing, drying, and galvanizing. This formwork system combines the steel bars in the concrete floor slab with the construction formwork to form a load-bearing component that can withstand the dead weight of wet concrete and construction loads during the construction stage, and this component can be used as a lateral support for steel beams during the construction stage. During the use phase, the steel trusses work together with the concrete to bear the use loads.

1. The stress mode and combination mode of the truss floor slab are reasonable, and it has the overall rigidity of cast-in-place concrete. It can easily complete the construction and use of two-way slabs, while the lower skin of ordinary profiled slabs is perpendicular to the direction of the ribs and the steel bars cannot be installed.

2. When the spacing between beams during construction is more than 3 meters, ordinary profiled plates will basically need to be equipped with temporary supports; the maximum unsupported spacing of the steel truss formwork can reach 5 meters.

3. Temporary holes are made on the truss formwork, which basically does not require reinforcement, and it is easy to lay mechanical wires and pipes.

4. The steel plate does not participate in the stress, does not require fire-resistant and anti-corrosion coatings, and does not need to worry about repair problems after fire. It is safe and economical. The bottom of the plate is flat and the clear height is guaranteed. The two-way rigidity of the floor plate is consistent and the earthquake resistance is good. It solves the problem of two-way distribution of closed plates. The steel bar spacing and the thickness of the concrete protective layer are guaranteed

5. The design and construction of two-way slabs are simple, suitable for large-span factory buildings, with reasonable coating, reliable stud welding quality, no need for penetration welding at the ends, and good floor shear resistance.

6. Use rust removal and anti-rust processes such as silanization, phosphating, washing and drying, galvanizing, etc., and seal and store in a dark place.

Recommended News

Recommended News

-

Say Goodbye to Water Leaks! Resin Tile Drip Edge: The "Invisible Guardian" Protecting Your

2025-07-19 04:14:16

-

Winter Workshop Turned "Ice Cave"? Time to Cover Your Roof with a "Thermal Blanket&quo

2025-07-16 11:08:03

-

Resin Tiles vs. Color Steel Tiles: How to Choose the Right Roof for Your Rural Self-Built Home?

2025-07-12 01:07:14

-

Why Don’t Color Steel Sheets Rust? The Secret Lies in Their "Metal Sun-Proof Coat"!

2025-07-03 03:12:00

-

GREEN Steel, AI Builders & Solar Skins: Future of Steel Construction!

2025-07-02 11:45:35

Contact us

Contact us

—— Contact:Ms. Zhang

—— Tel:(+86)18399688883

—— Email:18399688883@163.com

—— Url:https://www.tianxingmaterials.com

—— Address:Horgos City, Ili Kazakh Autonomous Prefecture, Xinjiang, China